Our machine design services utilize 19 years of experience in manufacturing. We begin with what your needs are and work together with you and your team to get the professional, efficient results you are looking for. We can provide any – or all – steps of our process from design, to models, to fully constructed production services installed in your warehouse.

Process Automation

In many cases in manufacturing the process grows over time and often this growth is simply tacked on to the current process. By putting a manufacturing process through a process mapping analysis, we show inefficiencies in areas such as wasted movement, unbalanced flow, or steps that are experiencing waiting. All of these indicators are nonvalue added steps to your process and should be eliminated to increase your profitability and efficiency. BPS can provide the process flow analysis to your process and help you save money and time.

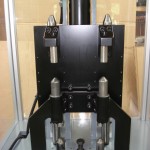

- Automated Press

- Detail of Automated Press

- Automated Booting Machines

- Electrical Panel – Booter

- Operator Panel – Booter

- Semi-Automated Manual Line

- Automatic Rolling Station | Semi-Automatic Manual

- Ultra-Sonic Welder | Semi-Automatic Manual

- Pin Prep Station | Semi-Automatic Manual

Sample Machine Designs

The scope of our services includes:

- Product development

- Design

- Prototyping and 3D modeling, as well as 3D printing services

Our customizable solutions include:

- Utilization of components already in hand to save you money

- Retrofitting of current machinery for customization or to increase output

- Upgrading of existing machinery to improve throughput or accuracy

- Providing rebuilt machine components to keep equipment costs down

A few examples of our work are:

- Automated press stations that replace hand operated Arbor presses, improving throughput, ergonomics, and factory safety

- Multi-station assembly processes that are connected by conveyors

- Rotary dial tables with multiple integrated automatic stations